Ceramic Tipped Doctor Blades – The Duroblade

The Rolf Meyer Duroblade is a technological breakthrough. By combining ceramic doctor blades with ceramic anilox rollers, the Duroblade® not only allows for fast payback, but it will boost your process and help you find your niche in an increasingly competitive world.

BTG is the inventor and producer of the Duroblade, successfully introducing the Duroblade to the market in 1986. BTG’s long standing experience enhancing steel with ceramics for increased wear-resistance led them to develop this unique blade which was designed specifically for friction (cylinder) and abrasion (ink). This means that the Duroblade is perfectly suited for use with ceramic anilox cylinders as well as gravure cylinders with engraved, ceramic rolls.

Duroblades are ready-to-use. No break-in period is required. The hard-faced tip wears slowly and evenly, providing a virtually constant working edge, thus ensuring consistent quality throughout your printing run. Both the product and the manufacturing process are patented. BTG’s quality control ensures perfect blade straightness and excellent edge quality across the entire blade length, as well as consistent quality from blade to blade. BTG Eclépens S.A. has a quality management system in conformance with ISO 9001.

Benefits

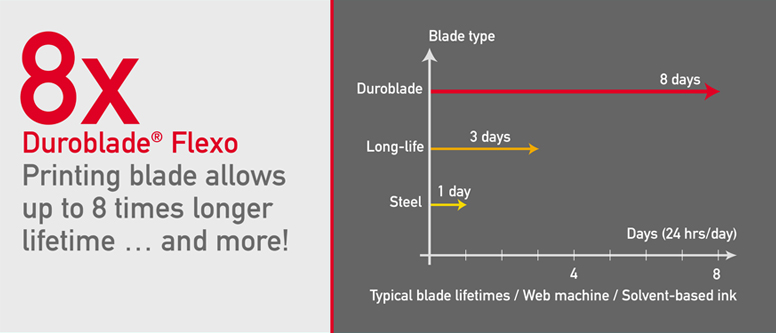

- Substantially longer blade life (6-10 times longer than steel)

- Increased blade chamber seal lifetimes

- Better sealing of the doctor chamber, hence cleaner production and less waste

- No run-in time – less waste

- Constant printing quality during the life of the blade

- Improved wiping of the anilox cylinder

- Reduced scoring lines due the lack of bur formation

- Increased press uptime

- Added safety from fewer blade changes and less sharp blades.

Blade Wear

It is a well-known fact that traditional steel and plastic printing blades wear quickly and unevenly. The wear process that occurs at the blade tip is influenced by many factors, such as linear blade load, printing press speed, pigment type and ink viscosity. Wear at the blade tip, resulting in material removal, occurs through a complex combination of sliding wear against the engraved roll, as well as abrasive wear caused by pigment particles. With a ceramic-tipped blade, pigment particles can’t plastically deform or cut the surface. Consequently, only a micropolishing effect is produced, which explains the low wear rate.

Constant Printing Quality

While printing quality from standard steel blades varies from break-in to blade change, ceramic tipped blades provide constant quality throughout their entire service life. Furthermore, they allow you to reach excellent printing quality faster, since no run-in time is required for these blades.

Longer Lifetime – Increased Productivity

The benefits cited above all contribute to increased productivity, through reduced downtime due to blade changes, constant quality and fewer defects resulting in less paper/foil to recycle.

Scoring

Scoring lines are a serious problem for ceramic anilox users. Metal shavings (burring) are thought to be one of the principal causes of cylinder scoring, as they get caught between the doctor blade and the cylinder. The ceramic-tipped blade reduces scoring because the ceramic edge of the blade contacts the cylinder instead of bringing steel into contact with the anilox. Hence, no metal shavings and slivers wear off the blade, which means that there are no metal particles in your ink chamber. Running with ceramic can dramatically reduce or even eliminate score lines. There is no cause for concern regarding the ceramic coating damaging the anilox because the hardness of the ceramic coating on the Duroblade is 850 – 900Hv and the hardness of the ceramic on the anilox roll surface is 1200 – 1500Hv.

It recommended that magnets are fitted to your ink system and that ink systems are cleaned before using the Duroblade.

Specifications

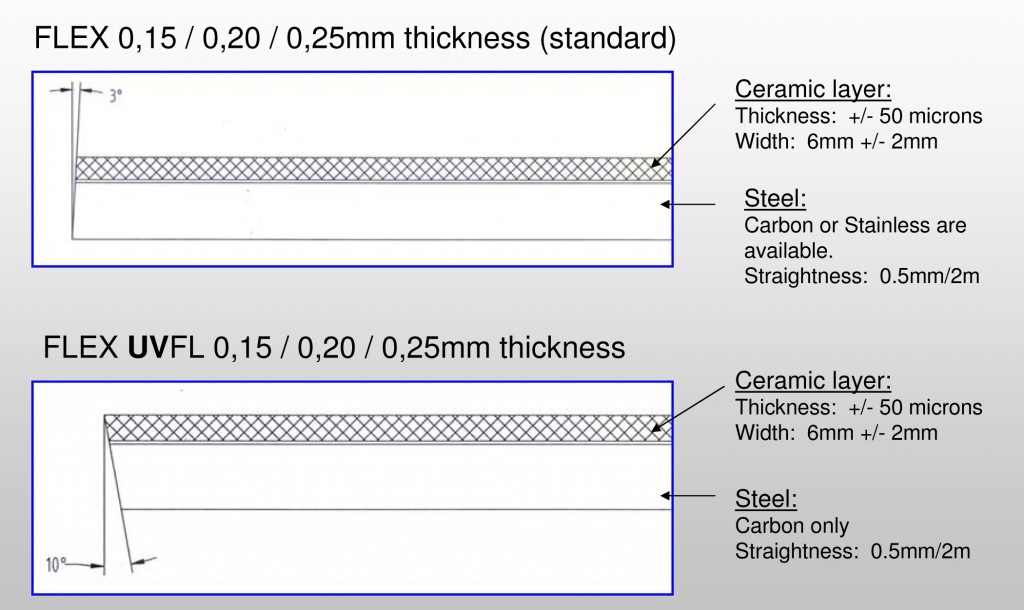

The Duroblade Flexo series is available in both standard steel and stainless steel. This blade is cut to length by BTG and supplied in pre-cut lengths as opposed to rolls.

Specific tip designs unique to UV inks are available due to the different viscosity of UV inks.